In recent days, the research team led by Kaijun Wang from School of Environment at Tsinghua University has achieved a significant breakthrough in the field of continuous-flow aerobic granular sludge research. They successfully upgraded the existing AAO process (with a daily processing capacity of 2.5×104 m3) to a large-scale continuous-flow aerobic granular sludge process. The research revealed that hydraulic shear force and feast/famine conditions are key factors in the granulation under continuous-flow conditions. Additionally, the study uncovered that under aerobic-only conditions, simultaneous nitrification, denitrification, and phosphorus removal occur, constituting the primary pathway for pollutant removal in the system. This accomplishment represents a milestone in technical innovation within the environmental sector, providing robust support for more efficient wastewater treatment.

With the continually increase of urban population, municipal wastewater treatment plants face the formidable challenge of improving effluent quality, increasing processing capacity, and reducing energy consumption within confined land areas. Aerobic granular sludge (AGS), settling significantly faster than activated sludge, offers the capability to simultaneously remove carbon, nitrogen, and phosphorus. In comparison to traditional activated sludge processes, AGS processes can reduce land area requirements by up to 75% and achieve energy savings of as much as 63%. However, the successful application of AGS processes has been limited to sequencing batch reactors, and breakthroughs in aerobic granulation under continuous-flow conditions are yet to be realized.

In this study, a microaerobic-aerobic configuration with internal separators was implemented to upgrade an existing activated sludge process (2.5×104 m3/d) to a continuous-flow AGS process. After one month of initiation, the initially inoculated flocculent sludge gradually transformed into granular sludge. During stable operation, the average particle size of the sludge increased from 31.9 to 138.5 μm, with the proportion of sludge particles >200 μm rising from 0 to 28.9%. The average SVI30 was 51.4 mL/g. The 95th percentile concentrations of effluent COD, NH4+-N, and TN were 35.0, 1.2, and 13.3 mg/L, respectively. DPAOs were enriched in the granular sludge with an abundance of 3.29%, which is 7.3 times and 10.3 times that of the inoculated sludge and flocculent sludge, respectively.

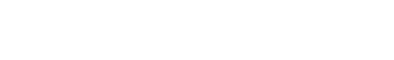

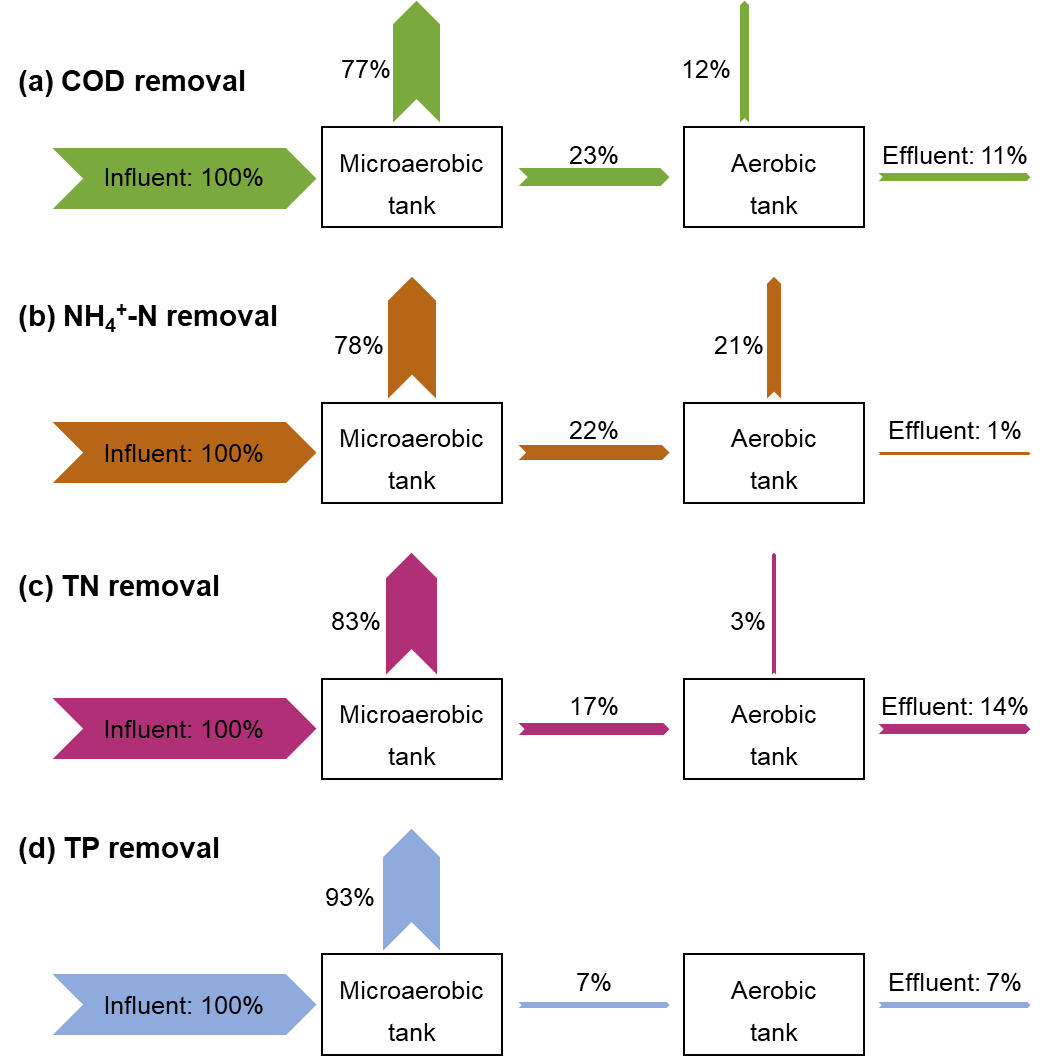

The investigation has unveiled that the microaerobic tanks play a crucial role in the removal of COD, NH4+-N, TN, and TP, constituting 77%, 78%, 83%, and 93% of the average daily load, respectively. In contrast, the contributions of the aerobic tanks to removal were limited, accounting for only 12%, 21%, 3%, and 0%, respectively (Fig. 1). To simulate the profiles of substrate and dissolved oxygen permeation within granules, the study employed a kinetic model (Fig. 2). The results showcased a swift decrease in dissolved oxygen concentration along the granule's radius, resulting in the formation of anaerobic/anoxic inner layers—except in cases with a radius of 25 μm, dissolved oxygen concentration of 0.5 mg/L, and substrate of 36.7 mg/L. This suggests that despite the relatively smaller particle size of sludge cultivated under continuous-flow conditions, stratification persists in microaerobic chambers under low dissolved oxygen conditions. Small particles within the range of 100~200 μm (constituting over 65% of the total) can effectively form aerobic outer layers and anaerobic/anoxic inner layers, facilitating the simultaneous removal of carbon, nitrogen, and phosphorus.

Traditional biological phosphorus removal necessitates the physical separation of electron donors (organic matter) and electron acceptors (oxygen/nitrite/nitrate). Achieving net phosphorus removal under continuously aerated conditions poses a significant challenge. However, the study's disclosure of the continuous-flow biological phosphorus removal process in microaerobic tanks challenges this conventional understanding. This groundbreaking revelation holds the potential to revolutionize wastewater treatment strategies and open avenues for more efficient and sustainable practices.

Fig. 1. Mass balances of (a) COD, (b) NH4+-N, (c) TN and (d) TP

Fig. 2. Profiles of DO and COD in aerobic granules with radii of (a) 25 μm, (b) 50 μm, (c) 75 μm, and (d) 100 μm

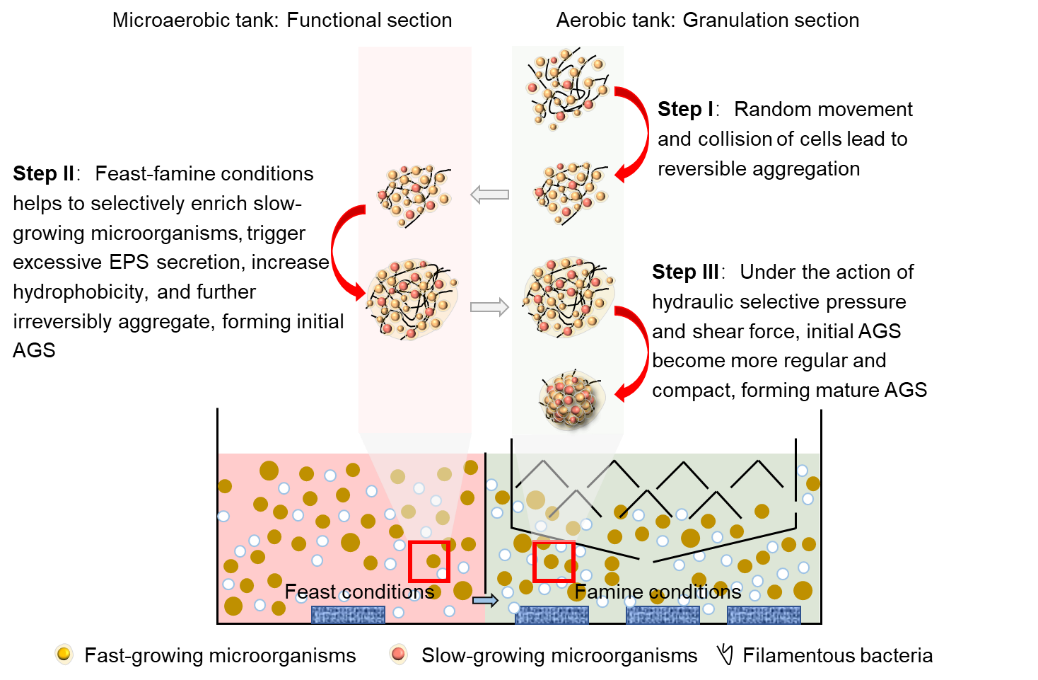

Furthermore, this study, utilizing the computational fluid dynamics-population balance model and COD degradation curve, has unveiled that the micro-oxygen-aerobic coupled precipitation reactor's configuration furnishes the essential hydraulic shear force and conditions of abundance-starvation conducive to particle formation. Additionally, a granulation mechanism within a microaerobic-aerobic configuration with internal separators is proposed (Fig. 3). Step I involved aerobic tanks, where favorable mixing conditions were created by a flow pattern with multiple vortical cells. These conditions increased the random movement and collisions of microorganisms, resulting in reversible aggregation. However, microorganisms in the aerobic tanks experienced a period of starvation and their growth was limited owing to substrate limitations. Step II involved the initial AGS formation. When sludge returned to microaerobic tanks, microorganisms underwent a feast period. The feast conditions selectively enriched slow-growing microorganisms, stimulated the excessive secretion of extracellular polymeric substances, and increased the hydrophobicity of bacterial surfaces, thus promoting irreversible aggregation and leading to the formation of initial AGS. Step III involved the formation of mature AGS. In aerobic tanks, shear forces acted on the initial AGS, resulting in a more regular and compact structure that ultimately led to the formation of mature AGS.

Fig. 3. Proposed granulation mechanism

On November 15th, the above-mentioned achievements were published in Water Research under the title "Full-scale upgrade of activated sludge to continuous-flow aerobic granular sludge: Implementing microaerobic-aerobic configuration with internal separators." Cheng Yu, a Ph.D. student from School of Environment at Tsinghua University, Class of 2018, served as the first author of the paper. Professor Kaijun Wang from School of Environment was the corresponding author. Kaiyuan Zhang, Ruiyang Liu, and Pingping Zheng from Beijing Huayide Environmental Technology Co., Ltd., were co-authors of the paper.

Paper link:https://www.sciencedirect.com/science/article/pii/S0043135423013106