Now that oxygen carrier materials can be manufactured at an industrial scale, chemical looping combustion technology could help generate clean heat and electricity with near zero emissions.

Technology for capturing carbon dioxide and storing it permanently underground is expected to be vital in strategies to restrict global temperature rises, according to an April 2022 report released by the United Nations Intergovernmental Panel on Climate Change. Chemical looping combustion (CLC) is recognized as one of the most innovative CO2 capture technologies because of low energy penality. An important step in this direction is a new industrial means of producing an affordable solid metal oxide1 – a perovskite oxygen carrier material developed by a Tsinghua team in 20212.

Zhenshan Li’s team have developed an affordable way to produce an efficient metal oxide-based oxygen carrier . This advance, he says, should enable chemical looping combustion to be incorporated into power generation systems, significantly reducing the amount of CO2 emitted.

Efficient production of the oxygen carrier should enable the power generation industry to incorporate an emerging, highly efficient carbon capture technology into its combustion processes, explains Zhenshan Li, who leads the Tsinghua team.

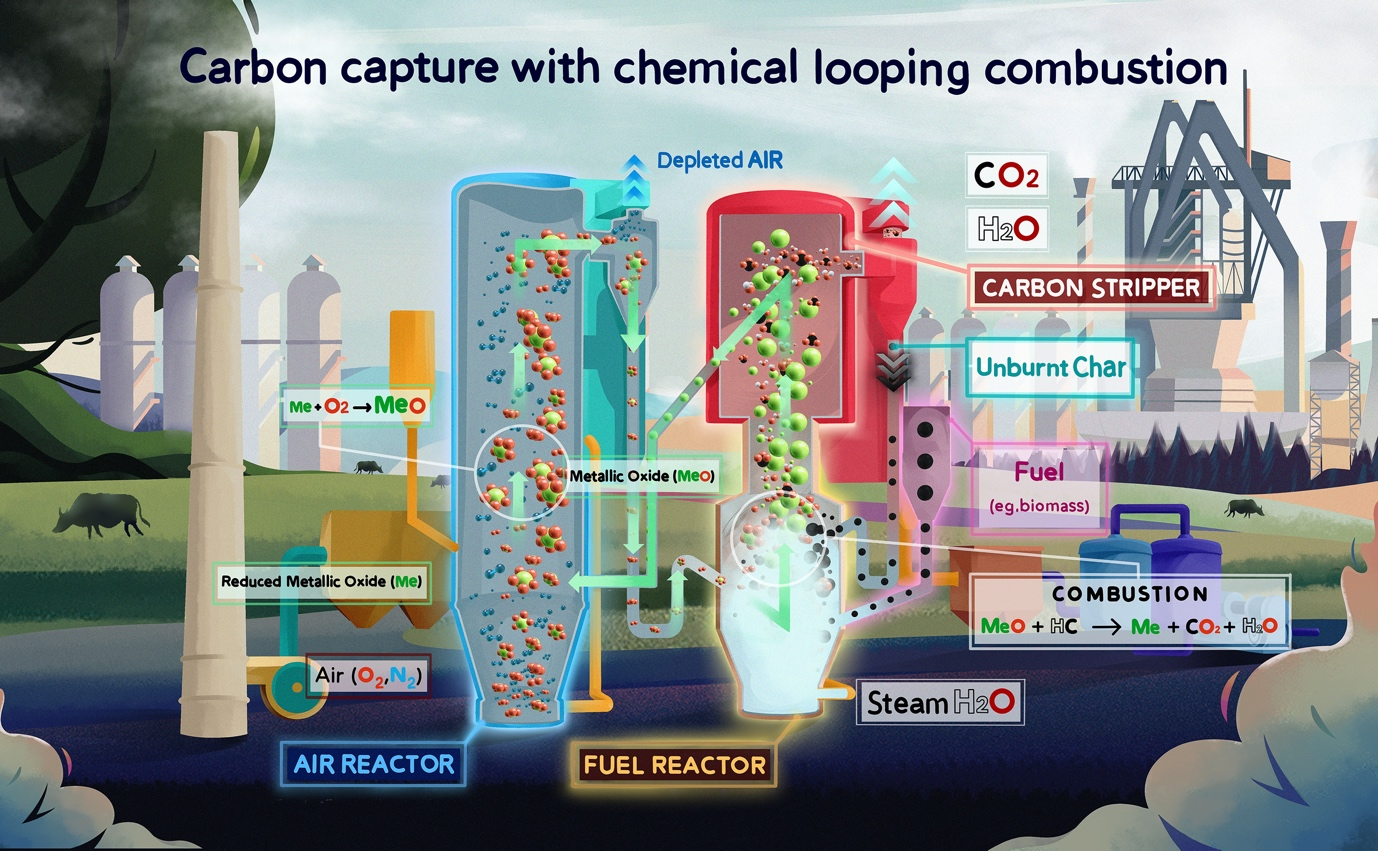

Chemical looping combustion technology is more efficient than existing carbon capture technologies, he says. The flameless combustion approach has just two end products: steam and carbon dioxide. The former can be used to run steam turbines, while, unlike other technologies, the carbon dioxide produced by CLC is pure enough to be sequestered immediately without the need for further expensive and energy-intensive processing.

CLC relies on adding solid oxygen carriers, rather than oxygen gas, during the combustion process, explains Li. “The solid oxygen carrier is then able to more efficiently generate gaseous oxygen in the fuel reactor environment,” he says.

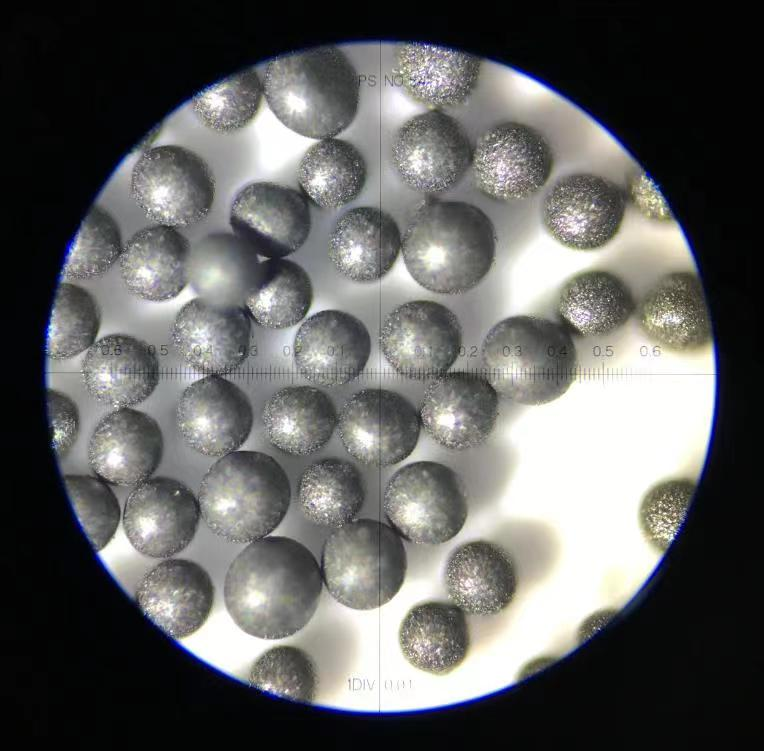

A perovskite oxygen carrier material developed by a Tsinghua team in 2021, after calcination.

A workable oxygen carrier

The identification of a suitable oxygen carrier had been holding back attempts to scale-up CLC technology. Most researchers have focused on using perovskite oxides containing precious and transition metals. These are too expensive for this purpose, says Li. “The oxygen carrier material must be cheap and environmentally friendly,” he says.

In 2021, Li’s team at Tsinghua’s Department of Energy and Power Engineering published in the Chinese Journal of Chemical Engineering on an inexpensive perovskite oxide (CaMn0.5Ti0.375Fe0.125O3-δ) with excellent oxygen transfer capacity and stability2. Now, the same team has revealed, in the Chemical Engineering Journal, a route to manufacture this perovskite oxide at volumes suitable for industrial use of CLC1.

The new production protocol is an adaptation of a well-known particle production method – spray drying – where a liquid slurry is atomized into droplets before being flashed dried to form solid particles. “The traditional spray drying method produces particles that are < 100 μm, but chemical looping requires an oxygen carrier particle size of 100 to 300μm,” explains Li. Several changes were made to increase the size of particle produced, including pressurizing the liquid slurry before spraying and adjusting the drying temperature.

Using their new protocol, Li and his team can continuously manufacture the perovskite oxide at a rate of roughly 2500 kg/h. The researchers also tested their new particles under conditions that closely mimic those of a CLC system, finding that their physical and chemical properties were the same as those produced previously by large particles produced in small batches in laboratories.

CLC has not yet been implemented at an industrial site, but pilot plants are starting to emerge, says Li. These include a 30 kW pilot unit at Tsinghua University, a 100 kW unit and the world’s largest 5 MW demonstration unit in the city of Deyang in southern China, all designed by his team.

Pressurizing a perovskite oxide liquid slurry and adjusting the spray-drying temperature in the above device produced particles at a useful size.

References

1. Liu, L., Zhenshan, L., Wang, Y., Li, Z., Larring, Y. et al. Industry-scale production of a perovskite oxide as oxygen carrier material in chemical looping. Chemical Engineering Journal 431, 134006 (2022). https://doi.org/10.1016/j.cej.2021.134006

2. Liu, L., Zhenshan, Li., Yi, L. & Cai, N. Evaluation of oxygen uncoupling characteristics of oxygen carrier using micro-fluidized bed thermogravimetric analysis. Chinese Journal of Chemical Engineering 32, 408-415 (2021). https://doi.org/10.1016/j.cjche.2020.11.023

Editor: Guo Lili